Oliver Balch takes a look at Svante, CarbonCure and Solidia, three eco-minded innovators that have won venture capital funding for their bid to drive down emissions in the construction industry

Green products are fast becoming a growth area in the cement industry. Innovation is coming from the labs of the sector’s big players, like Holcim, Cemex, and HeidelbergCement, as well as from a raft of eco-minded start-ups. Partnerships between the two are also becoming increasingly common, at both the development and commercial stage. Here we take a look at three leading proponents of new technologies:

SVANTE

Svante (formerly known as Inventys) is leading the charge in the long-awaited, but still emergent field of carbon capture and storage (CCS). The Vancouver-based firm has developed a technology based on nano materials (called “solid sorbents”) that permit CO2 to be captured from industrial facilities at multiple scales.

The captured CO2 is then concentrated and packed for safe storage or industrial use, all in around one minute. Svante’s ability to produce concentrated volumes of carbon in specific tailored volumes smooths the link between supply and demand. (Historically, utilisation requirements are lower than CO2 production, requiring CCS to be scaled down, which pushes up costs).

Svante is currently constructing a manufacturing plant for its advanced filter system, which it anticipates will be capable of removing 3m tonnes of CO2 per year. The young Canadian firm, which initiated a four-year pilot of its technology at Holcim’s Richmond plant in Canada back in 2019, has secured nearly $200m in investment since its inception.

CARBONCURE

Capturing carbon from hard to abate sectors such as cement is only one part of the CCS quandary. There’s also the question of how to store or re-use it afterwards. Enter CarbonCure, which has developed a technique for injecting CO2 (via a “valve box”) at the point when cement is mixed with water and sand to create concrete. The CO2 reacts with calcium ions from cement to form the nano-sized mineral, calcium carbonate, which becomes embedded in the concrete.

This reaction increases the strength of both ready-mix and precast concrete, thus allowing concrete producers to reduce their use of cement (and consequently reduce their carbon emissions). Over 300 plants are using CarbonCure’s solution at present, resulting in the supply of a reported seven million cubic yards of low embodied carbon concrete to date. Back in 2018, the company was one of 10 inaugural participants in Holcim’s then new six-month accelerator programme for disruptive startups (CarbonCure’s industry advisory council counts global head of solutions and products among its members).

The Nova Scotia-based firm has since gone on to win funding from Amazon’s Climate Pledge Fund, Bill Gates’s Breakthrough Energy Ventures and UK venture capital firm 2150 (See Paving the road to net-zero with bricks made of plastic waste).

SOLIDIA

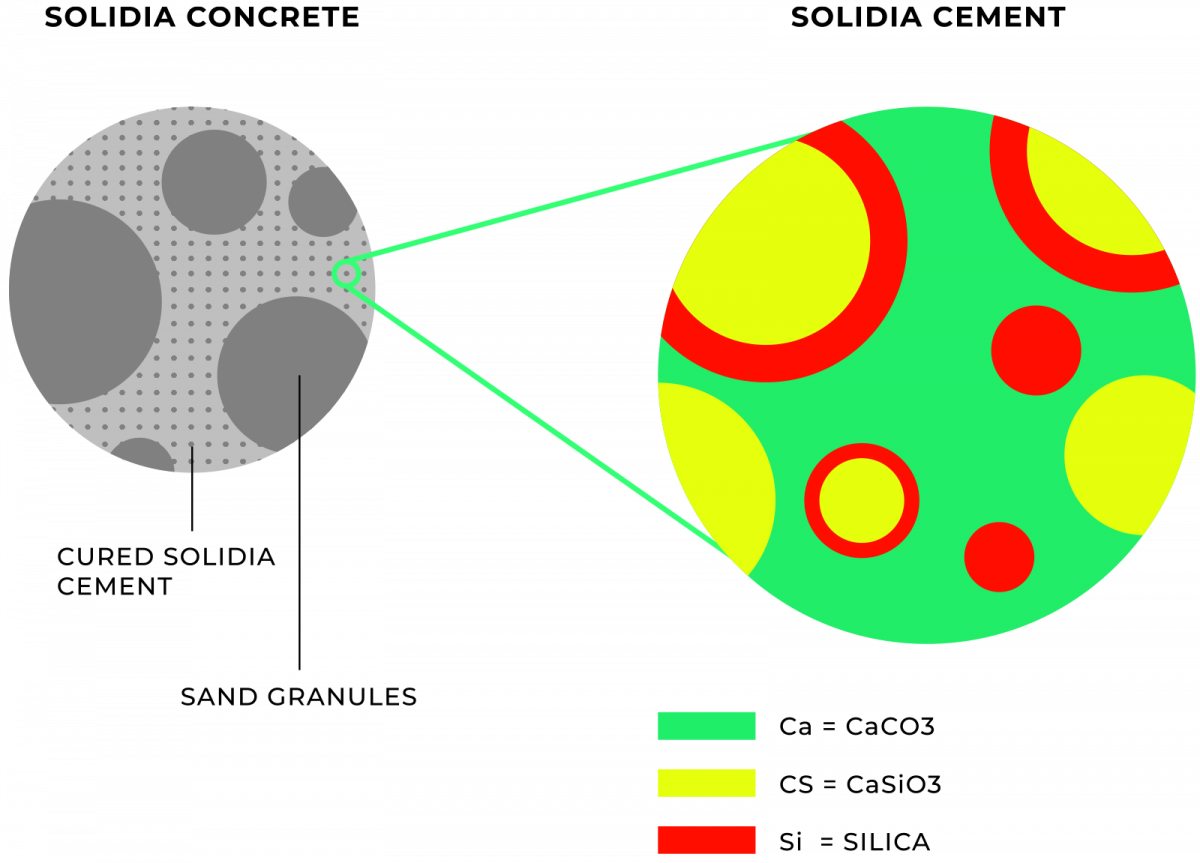

As one of the final stages of the concrete manufacturing process, the manufacturer is required to maintain the concrete mix at specific moisture and temperature levels for an extended period. Solidia’s breakthrough involves sequestering CO2 during this particular stage, known as curing. This relies on the properties of Solidia’s patented cement chemistry, which is comprised primarily of low-lime calcium silicate phases (as opposed to standard high-lime alternatives).

The cement’s unique chemistry facilitates the absorption of addition CO2 during the curing process, when CO2 (from waste flue gas) reacts with the calcium silicate phases in the presence of moisture to form calcium carbonate (similar to natural limestone). The end result is a concrete product with locked-in carbon that is intrinsically stronger as well as causing 30% fewer emissions. The technology, which can be used in existing concrete plants without modification, secured $78m in financing earlier this year from a group of investors that included Bill Gates’s Breakthrough Energy Ventures. Existing investors include BASF, BP and Holcim, among others.

Other innovators to watch in the sector include Ecocem, a cement substitute derived from granulated blast-furnace slag; CarbonBuilt, a hardened cement using CO2 from flue gas; and Alegina, which produces draining slabs and paving stones from crushed oyster shells.

CCS sustainable construction Holcim Svante carbonCure Solidia